The Overbuilt, Exceedingly Generous 10ML-II Barrel Design

When designing a barrel and suitable thickness for a given load, Lame's equation is one of the design components.

]

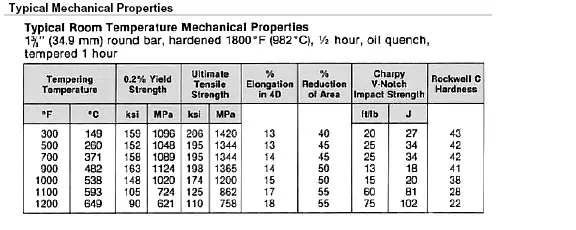

The above data is the typical mechanical properties of commonly available 416SS. This specific data refers to “Carpenter Stainless Type 416 BQ.”

Ultimate tensile strength is up to 206 kilopounds per square inch (ksi), which is 206,000 PSI. Generally, modern gun barrel materials exceed 105,000 PSI yield strength. Elasticity must be maintained in gun barrels, and the range of 26-32 Rc (Rockwell C scale) hardness has been determined as the appropriate, safe tradeoff.

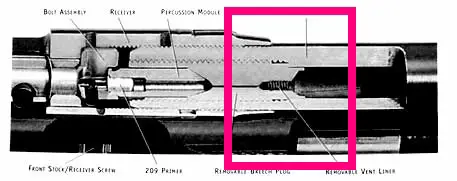

Using an internal pressure in excess of the 10ML-II maximum proof load, 50,000 PSI, and an allowable tensile stress of the typical gun barrel .2% yield strength above, 105,000 PSI (105 ksi) the figures have been plugged into Lame’s equation using an internal diameter of .505 inches.

Using these precise values, the result from Lame’s Equation shows a desired minimum wall thickness of .171 inches, and a barrel OD of .848 inches.

The wall thickness in the pressurized steel tubes program used is from Wm. C. Davis, Jr. It calculates by Lame’s Equation the desired minimum thickness of a tube subjected to internal pressure, and the criterion assumed is that the tangential stress area at the inner surface of the tube may not exceed the specified allowable tensile stress of the material. (Thick-walled tubes can withstand higher pressures than those indicated without bursting).

Inspection of the above shows that the Savage 10ML-II barrel has FAR more than this recommended minimum wall thickness in ANY part of its breech plug inclusive of the unthreaded portion or ANY primary combustion area, about 30% more thickness than required, and the 50,000 PSI value used to determine “this” minimum wall thickness not ONLY exceeds ANY Savage 10ML-II approved load, it also exceeds the highest reading ever recorded by Savage’s 10ML-II proof load—which happens to be in excess of a 55% overcharge of propellant by weight.

Despite all this, Savage Arms does not allow any charges in excess of recommended loads, nor does Savage Arms allow the use of any sub-bases or other materials beneath a bare sabot-- and specifically disclaims the use of sub-bases or other such materials.

For those that have been stunned by the Savage 10ML-II’s ability to withstand 129,000 PSI in destructive testing—maybe now you really shouldn’t be?

As this information validates, the 10ML was designed from the beginning to be the world’s safest muzzleloader, and from Henry Ball to Savage Arms Company, the criteria was to err only on the side of strength and safety. There was a lot of thought that went into this design and testing-- nothing was thrown together by happenstance.

© 2004 by Randy Wakeman

A special word of thanks goes out to Mr. Daniel Lilja, proprietor of Lilja Precision Rifle Barrels-- manufacturer of some of the finest and most accurate barrels in the world, for his kind assistance in supplying barrel design information. Information about Lilja barrels is found at http://www.riflebarrels.com . Mr. Lilja also has some fine articles on the fine art of barrel making on his site, regarding Barrel Making, Bullets & Ballistics, Long-range Shooting, and an excellent collection of hunting, shooting, and fishing stories that you may find of interest.

Postscript:

Several people have inquired about the "torture testing" inflicted on the 10ML-II by Savage Arms, prior to releasing it for sale to the consumer. Henry Ball's description follows. Please note that this was all done via remote firing in secured conditions, and is in no way an allowed procedure by Savage Arms-- nor license to ever exceed Savage's 10ML-II recommended loads. It is mentioned here for those who have expressed more than a casual interest in the 10ML-II's background.

Pressures during this torture sequence were recorded by radial transducer.

Initially, the 10ML-II was fired with a maximum recommended charge of IMR-4227 and a Hornady 300 gr. .452 MMP saboted bullet.

Then, the 300XTP was fired with a series of DOUBLE charges of powder. This pushed the pressures up into the 85,000 PSI range, with no damage to the test rifles. . No damage to the rifles was detected. The tests were conducted by Mark Kweicien.

Tests continued, pushing pressures up to 129,000 PSI. Tests were conducted on both Type I and Type II (current 10ML-II) rifles with the same results. No damage to the rifles.

This type of design integrity is unparalleled in the muzzleloading industry, a feat that has been replicated by no other production muzzleloader made today. On a consumer level, Savage recommended loads fall into the mid 30,000 PSI envelope. It is this type of prerelease testing, to over 250% of service load levels and absurd triple powder loads that offers today's savvy muzzleloading enthusiast a level of safety and quality never before obtained in a production rifle.