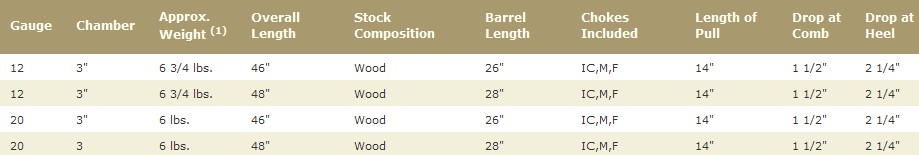

Weatherby SA-08 Deluxe 20 Gauge Autoloader

This is the first Weatherby brand autoloader I've had the chance to go through in many years. It is apparently made in Istanbul, Turkey, by Armsan or ATA. Armsan has been defined as a collaboration between Khan and ATA. Although I was advised that this model was from Armsan, that seems unlikely as it is clearly not a version of the Armsan A620, but instead appears to be essentially an ATA “CY Walnut” model using the captured forearm and the ATA trademark pair of gas pistons, one for light loads and one for heavy loads.

The test gun sent along by Weatherby is quite obviously a used gun, with very small scratches and handling marks on the wood finish, a prominent barrel line from normal wear, wear to the barrel extension, and a flagrantly fouled “heavy” gas piston (above). It is not unusual for test guns to be used, or previously reviewed as the case may be. Three choke tubes were supplied, the IC and MOD inscribed tubes from stainless steel, the FULL choke apparently from carbon steel. It is hard to discern from the Weatherby website what the SA-08 20 gauge barrel is threaded for, but on the supplied example it is for standard Browning Invector (WinChoke) choke tubes.

This Weatherby SA-08 26 inch barreled twenty gauge is light for a gas-operated auto at six pounds on the nose. Many of the autoloaders I've tested, Turkish and otherwise, have been equipped with ridiculously heavy triggers: triggers with a break weight far heavier than the gun itself. Thankfully, that isn't the case here, for after substantial initial take-up the trigger breaks at an average of 4 lbs., 1 ounce. The SA-08 Deluxe has a MSRP of $799, but street prices are in the $650-$675 area. The synthetic version is $599 MSRP, with street prices around the five hundred dollar mark. There is, in general, a lot to like about this model.

The walnut, getting increasingly hard to find in affordable guns is attractive, the forearm and buttstock evenly matched in color and tone. The barrel blued finish is evenly applied and a very nice change from the rough, unfinished matte barrels that are increasingly common. Instead of a vinyl crucifix or plastic shoulder-stabber, the factory recoil pad is more generous than most, a fairly soft durometer, and is well-finished to the buttstock as well. Overall, it is a sharp-looking autoloader, markedly better finished than the vast majority of value-priced shotguns out there. It shaves a clean quarter pound (or more) off the weight of most gas-operated self-loaders, equaling the six pound weight of the Franchi Affinity and Benelli M2 twenty gauge plastic-stocked recoil-operated autoloaders.

The light / heavy dual gas piston set may be puzzling to some, but I think it is an excellent and sorely overlooked approach. The gas piston does nothing different than a Remington 1100, Mossberg 930, Beretta 303 or Browning B-80 gas piston: so one fixed / solid piston cannot possibly control bolt speed and resultant ejection distance. In times past, whether a Browning B2000, Beretta 302 or 303, and so forth the idea was straightforward: you bought a 2-3/4 inch chambered gun for the most part, opting for a 3 inch gun (or just an extra barrel) for heavier hunting loads. But, some folks have been grousing a bit ever since, as they bought a "three inch magnum gun" but want to shoot weak target loads out of it, regardless. The solution is to drill out a gas port or buy the proper, 2-3/4 inch barrel.

The problem with drilling out a gas port is that it is a one-way trip: it is hard to sand metal back on. You've turned your Beretta 303 3 inch shotgun into a gun suitable for lighter loads, but one that can break links and generally shake itself to pieces if given a steady diet of heavy pheasant loads, much less a few 2 oz. three inch lead loads. With a new gun out of the box, there is no way to tweak it for the smoothest, most vibration and stress free operation. In the case of the Beretta A390, it was Cole Gunsmithing to the rescue with a set of five secondard gas vent springs so you could essentially have no secondary gas bleed for wimp loads, but can significantly smooth out your gun with higher intensity loads. They work like a charm. Beyond that, whether we like it or not mass-produced shotguns are individuals and your buddy bragging that "his gun" cycles popper loads is of no help, usefulness or comfort when your example does not.

For doves with a 20 gauge, I'm typically using 15/16 oz. B & P F2 loads, a bit more energetic than generic 7/8 oz. target type loads, or 1 oz. loads. Using the "heavy" Weatherby piston with B & P shells, in this gun, yielded a 3-4 foot ejection distance . . . essentially perfect. So, in my case with this gun it would be heavy piston only most of the time, changing to the light piston only if using lighter payload / slower velocity loads. Though very light for a gas auto, this six pound gun is a creampuff to shoot . . . helped by the gas operation, heavy piston, and excellent recoil pad.

The only operational point of note is the shell lifter release, found on the left side as shown above. I found it easiest to use (which you won't do very often) just by wrapping my forefinger around the front of the trigger guard and pushing back. It is easy to get used to.

With the Weatherby's fast handling, light weight, attactive walnut, polished blue barrel, well-finished and soft durometer recoil pad, as well its light factory trigger . . . it is the first autoloader of Turkish origin that I can happily recommend. For a sharp-looking walnut-stocked self loader, delightful to carry with no aftermarket trigger work or replacement recoil pad needed for most folks, it is a lot of gun for $650 2013 dollars, with the synthetic-stocked versions going for somewhere around $150 less than that. The choice is yours, but the walnut is my clear preference.

Copyright 2013 by Randy Wakeman. All Rights Reserved.

Custom Search

Custom Search