Choke

and Barrel Specs

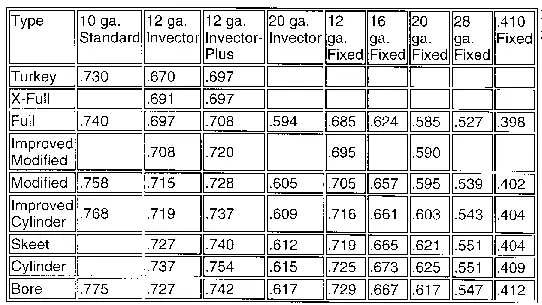

Choke Tube Muzzle Dimensions + or - .0015

Browning has always defined "shotgun" to me, and they have always been a leader as far as I can remember. The above chart tracks the Browning shotgun barrel and choke specifications inclusive of the differences from fixed choke to Invector screw choke to the current Invector Plus barrels and chokes. A perusal of the above information shows that many of the assumptions and old wives tales attributed to shotgun dimensions are just plain wrong.

You'll read in the literature about "standards," for example that .729 in. is the standard bore diameter for "American" twelve gauges, and .725 in. is the "European standard." Current Browning 12 gauge barrels are neither. It is fallacious to assume that any individual gun has either of those exact bore diameters-one of the reasons we need to mic our bores to begin to uncover the constriction / patterning relationship in an individual gun. Perhaps you've head the old advice that "if a dime won't fit down the muzzle of a 12 gauge, it is "full choke"? Well, maybe-- but maybe not. We need to pattern to see what any shell / barrel / choke combination actually does-- there is no other way, as "choke" is performance based, NOT constriction based, and what a choke tube is marked indicates neither.

Note that "cylinder" is a choke, not the same as actual bore diameter at all. It may be .010" over bore diameter, as in 12 gauge Invector specs, or it may be a constriction as in 20 ga. Invector specs, or 12 gauge fixed choke specs. While skeet shooting one afternoon, a few folks "assumed" that I was running the field with a modified or tighter choked 20 gauge, as all the birds were ink-blots. It wasn't the case at all-it happened to be a B-80 20 gauge with a cylinder Invector tube, so assumptions and appearances can be misleading.

Perhaps you've heard the notion that "those old Belgium Brownings are all really tightly choked barrels." Actually, that is normally not the case. What has happened, with the shift to plastic wad cups that eliminate contact between the shot pellet and the shotgun bore, less constriction is generally needed to achieve a certain pattern percentage. Added to that, the plastic wad cup reduces the potential "bore" of our shotguns by its own thickness and we are now effectively shooting a smaller gauge shell. This increases the choke effect at the muzzle as well, as the percentage of constriction goes up in concert. I wondered why my IC 12 ga. A-5's threw such beautifully dense, even patterns of 1-1/4 oz. #5 shot at 40 yards: far, far better performance than "improved cylinder" is supposed to have. That was eight hundred or so pheasants ago, and now the relationship of shell construction and constriction (though still an inexact trend) has become clearer to me. A plastic shot wad, .013 in. constriction, relatively large nickel-plated lead shot, and a 1-1/4 oz. or heavier payload can produce patterns far better than we might assume at first blush, perhaps astonishingly so.

The Winchester 101 was the first production shotgun to have screw-chokes; by now standard fare. The combination of new plastic wads of varying thicknesses, further progressive-burning shotshell powder development, and the gravitation to both heavier payloads left many manufacturers a bit puzzled, understandably so. Then, along came steel shot with thicker shot wads yet, and it became a further nightmare to dare stamp a choke tube with any particular performance designation. No matter what your choke tube marked, I guarantee you that it is "wrong." Choke tubes just aren't smart enough to know what loads we might feed our individual shotguns, so again-we desperately need to pattern our guns with the shells we are going to hunt or break clays with.

Most manufacturers have absolutely no clue what specifically a shotgun will do with all the loads out there, nor should they. For example, I can tell you of all the millions of shotguns ever sold, the number that were designed to perform with "Hevi-13" or "Winchester Xtended Range" high density shot. That's easy, even for me-- that would be zero. It is very difficult to design and manufacture a shotgun for projectile materials that have yet to be produced. Shot size, composition of shot, wad type, muzzle velocity, and payload weight all can dramatically affect what pattern a single gun can throw. There is no "standard" load that most manufacturers pattern with, and that remains part of the reason a designation on a choke tube alone can not possibly mean anything specific.

There are starting points, however vague. The best thing anyone can do is to establish a baseline through patterning with factory chokes and a specific load. If we have no idea where we start at, we don't know if we are really improving things or not-much less by how much. The Browning fixed choke constrictions above have always been a reasonable guideline for me.

Recommendations are necessarily vague, but for skeet or other 25 yard (and under) work, I like to see at least some constriction-- .003 in. to .006. For 27 yard 5- stand trap, there is no much thing as too dense of a pattern, so .030 to .035 in. constriction is a reasonable start.

For reasonably close game, out to 35 yards or so, the .015 in. constriction arena is a good starting point. When you need to be prepared for longer wing-shots; the .025 in. constriction chokes are a reasonable compromise. Not much looks good past 50 yards that I've seen.

Turkey chokes are a unique animal, as the maximum 24 inch 100% lethal pattern is not the goal, but more the density of the 8-10 inch fist we want to punch a head with. A trend is a .050 in or greater constriction extended tube with an extremely generous parallel section.

Most chokes today are "conical-parallel," meaning we have a tapered cone to give us our constriction, and a parallel (a.k.a. "cylindrical") section that has been shown to allow the shot mass to stabilize and reduce flyers. It is not that all factory chokes are garbage, some produce excellent patterns-but some are clearly better off not being used.

After we have a baseline of performance, the best thing anyone can do is go to http://www.trulockchokes.com/ and get a couple of similarly constricted extended Trulock "Precision Hunter" choke tubes to compare. I won't tell you they are the "only" choke tubes on the market by any means. I will tell you that, as a generality, there are none better at twice the price.

Your pattern board will prove to you exactly what improvement you get. Particularly in the tighter constrictions, when used with larger shot, or with heavier payloads, the results may astound you. Expect particularly amazing results when compared against shorter factory tubes, like the standard Invector / Winchoke. If you have plastic fouling issues, you can also expect those to diminish or disappear altogether-- and make no mistake: crud clinging to the inside of a choke tube can destroy the proficient patterns we all seek, in one big hurry.

Copyright 2007 by Randy Wakeman. All Rights Reserved.